ECONOMY

Realization of the

Circular Economy

Examples of Our Initiatives

We Have Realized the Circular Economy for Over 20 Years

Theories and plans alone are insufficient to realize sustainability and the circular economy. We also need vehicles to carry waste, processing equipment, technologies and expertise to convert waste into resources and materials, and a network that supports circulation. The REFINVERSE Group, with these execution resources, has a track record in this of over 20 years.

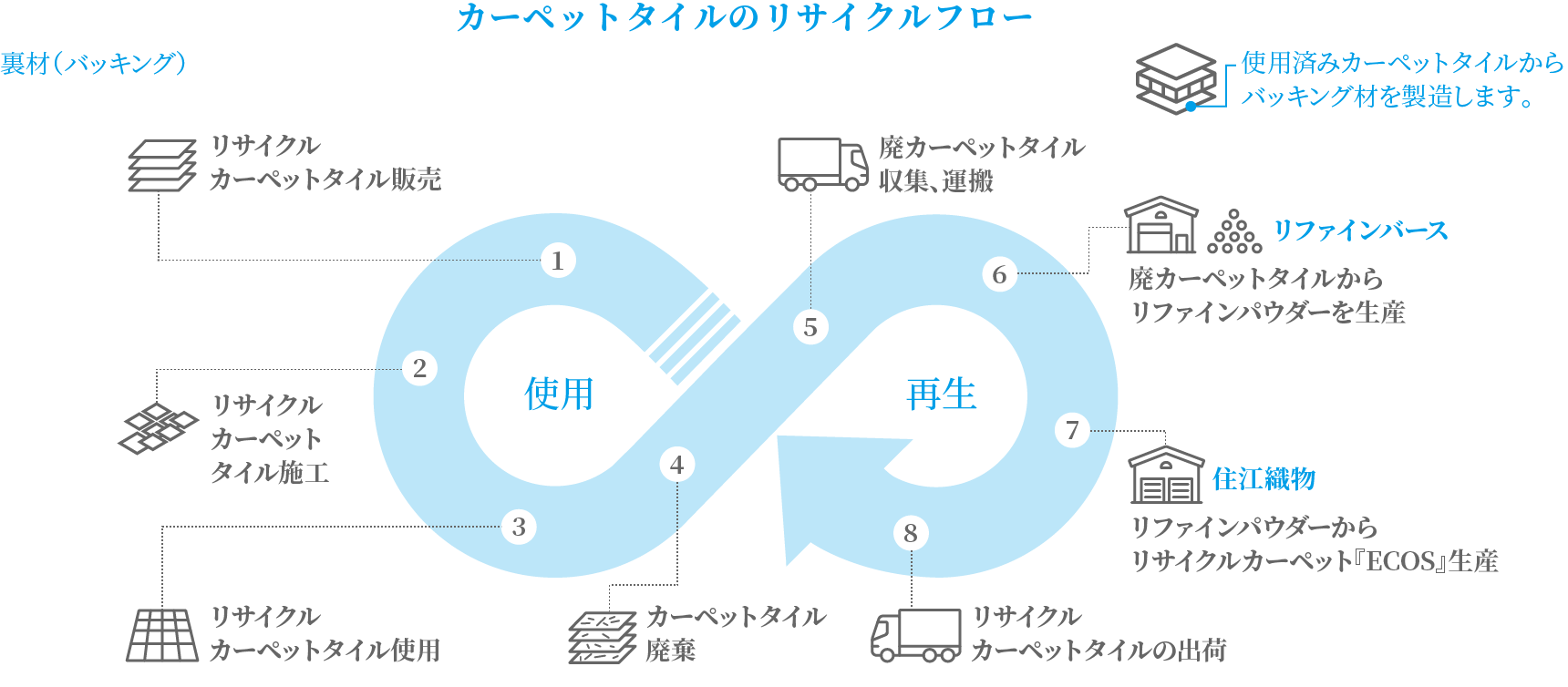

- Suminoe Textile and REFINVERSE

Separation by constituent material is a quality requirement sought for recycled materials in the recycling of carpet tiles. Existing technology fails to satisfy this requirement. Therefore, we developed our own separation technology and succeeded in providing cost-competitive recycled materials by mass production.

Nevertheless, this is not sufficient as a truly sustainable mechanism. That is because there are differences in the processing characteristics when making carpets with conventional petroleum-derived virgin resins and recycled resins. That means productivity decreases when processing recycled resins on existing carpet production lines. As a result, the cost of manufacturing carpets rose.

Accordingly, we devised from scratch a processing method most suitable for the recycled materials we provide in collaboration with Suminoe Textile. We have developed an unprecedented production line dedicated to recycled carpet tiles. This has led to the birth of the ECOS series of recycled carpet tiles that boast the world’s highest level of environmental performance.

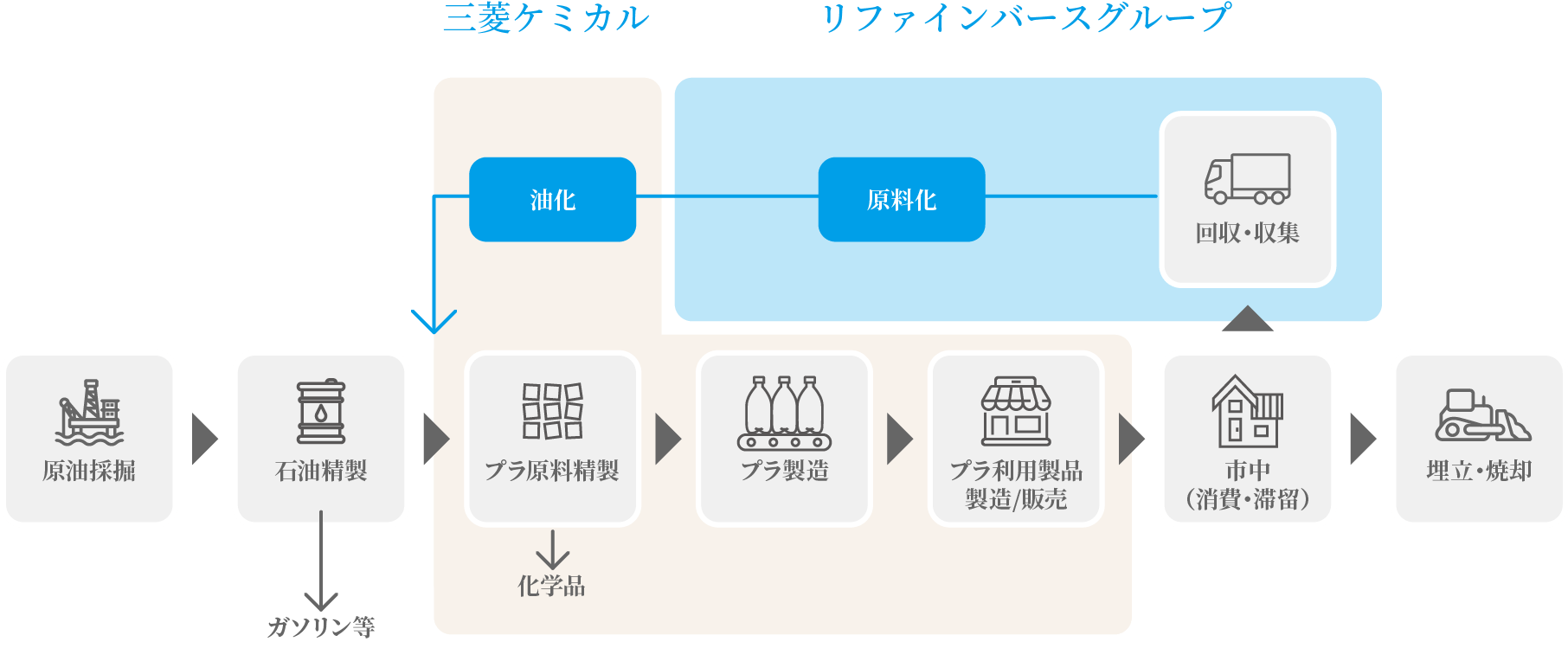

- Mitsubishi Chemical and REFINVERSE

In Japan, 8.5 million tons of waste plastic are generated annually. We can process only just over 10% of this amount using conventional recycling technologies, due to technical and quality issues. As a result, most waste plastic is thermally recycled or incinerated.

Against this backdrop, a technique called “chemical recycling” is attracting attention. This is a new initiative to circulate waste plastic as a resource instead of incinerating it as was conventional. The aim is to realize carbon neutrality.

Chemical recycling makes it possible to recycle some of the waste plastic that was previously thermally recycled or incinerated. It is expected that this technique will be used in recycling in the future. We, together with Mitsubishi Chemical, have already started preparations to use chemical recycling on a commercial basis with the goal of starting business in 2023. We will aim to promote the transition to the circular economy by enabling the use of waste plastic as a resource instead of using petroleum.

日本語

日本語